5 Inventory Planning Mistakes That Are Costing Your E-Commerce Business Money

Poor inventory management can drain your profits faster than almost any other business mistake. Learn these critical pitfalls to protect your e-commerce business's bottom line.

Running an e-commerce business is challenging enough without making costly inventory mistakes. Yet, many businesses continue to lose money through inefficient inventory planning. Let's explore the five most expensive inventory planning mistakes and how to avoid them.

1. Over-purchasing Leading to Excess Inventory

One of the most common and costly mistakes is buying too much inventory. While bulk purchases might seem like a good deal initially, the hidden costs can be substantial:

- Storage costs for excess inventory

- Tied-up capital that could be used elsewhere

- Risk of obsolescence

- Increased insurance costs

"The true cost of excess inventory isn't just storage - it's the opportunity cost of capital that could be driving growth elsewhere in your business."

2. Underestimating Lead Times and Stockouts

Stockouts can devastate your business, leading to:

- Lost sales

- Damaged customer relationships

- Reduced brand loyalty

- Competitors gaining your customers

The Real Impact of Stockouts

Studies show that 70% of customers will shop with a competitor when faced with an out-of-stock item. Here's how to prevent this:

- Implement safety stock levels

- Track supplier performance

- Use reliable forecasting tools

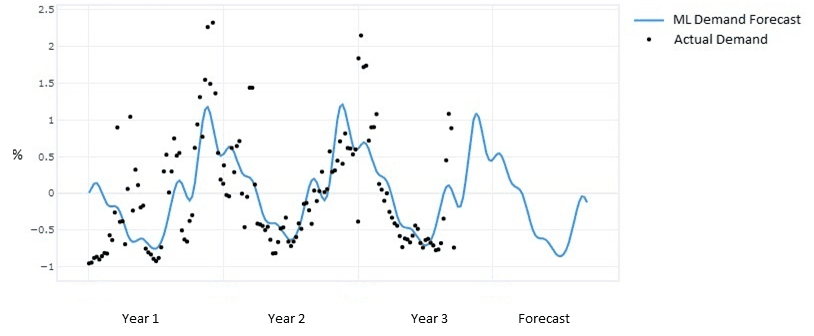

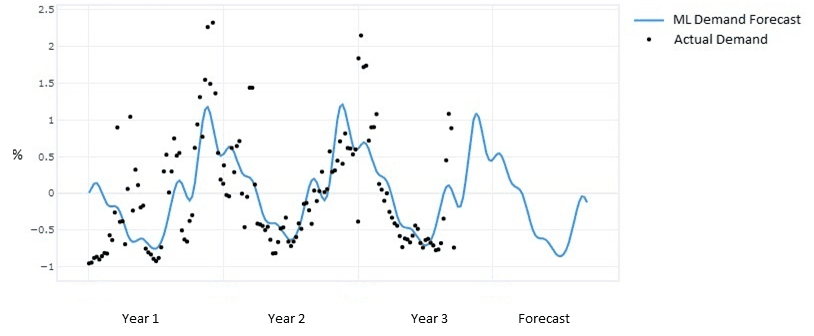

3. Ignoring Demand Seasonality

Seasonal demand fluctuations can make or break your inventory planning:

Image credit: Supply Chain Analytics Dashboard, 2024

- Holiday shopping spikes

- Weather-related changes

- Industry-specific patterns

- Special events and promotions

4. Relying on Manual Tracking Systems

In today's fast-paced e-commerce world, manual inventory tracking across multiple sales channels is a recipe for disaster:

// Old way: Manual Multi-Channel Tracking

const manualEcomProcess = {

amazon_inventory: "Spreadsheet tracking",

shopify_store: "Manual counting",

walmart_marketplace: "Daily updates",

error_rate: "High",

sync_delay: "24+ hours"

}

// Modern Solution: Integrated E-commerce System

const automatedEcomSystem = {

amazon_inventory: "Real-time sync",

shopify_store: "Automated tracking",

walmart_marketplace: "Instant updates",

error_rate: "Minimal",

sync_delay: "Seconds"

}5. Failing to Account for E-commerce-Specific Disruptions

Modern e-commerce businesses face unique supply chain challenges. Smart online retailers prepare for:

| Disruption Type | Impact | Mitigation Strategy |

|---|---|---|

| Flash Sales | High | Dynamic inventory buffers |

| Algorithm Changes | Medium | Multi-platform presence |

| Marketplace Suspensions | High | Channel diversification |

| Viral Product Demand | High | Scalable supplier network |

Building E-commerce Resilience

- Maintain inventory across multiple fulfillment centers

- Set up backup selling channels

- Implement automated repricing strategies

- Monitor social media trends for demand spikes

The Solution: Smart Inventory Planning

Avoiding these mistakes requires a systematic approach to inventory management. Modern solutions like Inventory Mate offer:

- AI-powered demand forecasting

- Real-time inventory tracking

- Automated reorder points

- Supply chain monitoring

- Seasonal trend analysis

Why Modern Tools Matter

Smart inventory management tools can:

- Reduce carrying costs by optimizing stock levels

- Prevent stockouts through predictive analytics

- Improve cash flow by freeing up capital

- Increase customer satisfaction with better availability

Take Action Today

Don't let poor inventory planning eat into your profits. With the right tools and strategies, you can:

- Optimize your inventory levels

- Reduce carrying costs

- Improve cash flow

- Enhance customer satisfaction

Ready to transform your inventory management? Try Inventory Mate free and see the difference smart planning can make for your business. Try Inventory Mate free

Remember, effective inventory management isn't just about avoiding mistakes—it's about creating a competitive advantage for your business. Start implementing these solutions today to see immediate improvements in your bottom line.